Clothing has emerged with the need to protect the human body from external factors and to cover at the same time. Today, clothing has been developed in a way that serves many purposes. Such as dressing up and adapting to the conditions required by the working environment, in addition to these needs. These developments are increasing day by day.

Fabric and clothing style play an important role in religious and social beliefs. From the earliest recorded history, a person’s clothing can give us an instant glimpse of their socio-economic status.

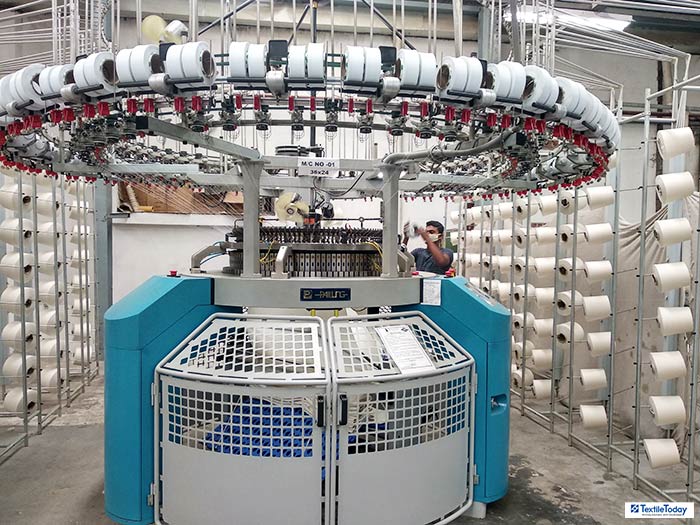

How are fabrics produced, which are the basic materials of clothing that you can find everywhere from luxury boutique stores to street markets? We will share with you the journey of fabric from raw material to clothing.

Raw Materials That Make up the Fabric

The raw materials that make up the fabric can be divided into three separate categories: Those derived from natural plant sources, those derived from animals, and those made by man.