What is Lycra?

Lycra is the trade name for spandex (elastane) fiber. Fiber types with high elongation ability are classified as elastomer (elastic) fibers, and these fibers are commonly known as lycra in our country.These fibers are fibers that show a very high elongation (400-800%) without breaking and can quickly fully recover at elongations up to the breaking point. Lycra is the trade name for this fiber with elastic properties.

Technically, it can be called elastomer fiber. It is a very flexible, strong, and durable fiber. It was discovered by the chemist C. L. Sandquist and Joseph Shivers. Lycra threads, in the simplest sense, are threads made of synthetic lycra fibers in filament form. Lycra, which has a very common usage area, is of great importance today. The characteristic feature of lycra fiber is its very high elongation ability and its ability to return without deterioration in its structure. Lycra fiber used products; It adds unique features such as comfort, fit, and freedom of movement. Lycra is a type of fiber that is generally elastic and pulls in width and length when washed.

These fibers are produced from natural rubber as well as synthetically.

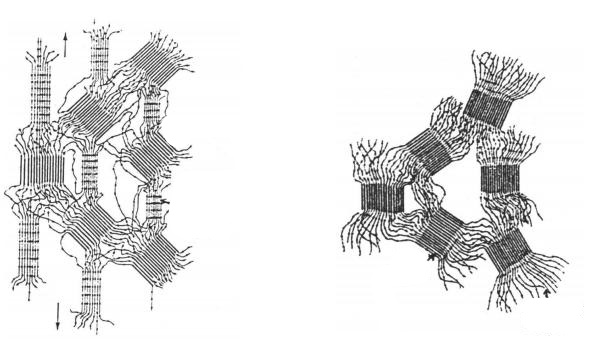

Figure 1.2 The structure of elastane that crystallizes (turns into a crystalline structure) when drawn. left, stretched right, relaxed.

Flexible fibers obtained from natural rubber have been used in the textile field for a long time. However, it has become difficult to meet such increasing requirements in recent years with only natural rubber fibers. Therefore, elastomeric materials that can replace rubber fibers were sought. As a result, some synthetic materials that are more flexible than rubber, at the same time resistant to abrasion, high chemical stability, lighter, easy, and well dyed have been obtained.

Today, the use of elastomer fibers has spread over a wide area and the products produced from the mixture of cotton, viscose, polyester, polyamide fibers, and elastomer fibers have entered daily use. These fibers consist of a molecular chain network and their high amorphous regions are linked by cross-links. In elongation, these amorphous regions are more oriented and crystallized in structure. The elongation continues until the crosslinks in the structure limit the further movement of the molecules. If more force is applied to the elastomer fiber at this point, molecular degradation occurs and elongation properties decrease.

Our lycra fabrics